Milling is an old technology but, many advancements have been made since the Neumann Machinery Company ball mill products were introduced in the early 1900’s.

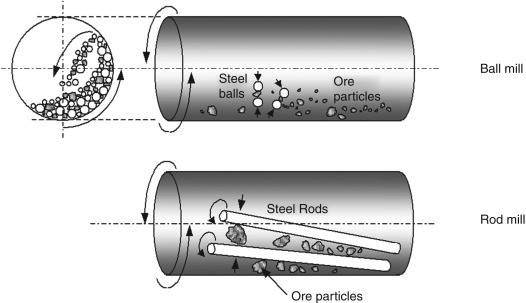

How Ball and Rod Mills Break Down Particles

The primary function of a ball mill is to reduce larger particles to fine particles. In the base metals mining industry this Particle Size Reduction (PSD) allows downstream processes to more fully access the metal content embedded in the ore. Balls or rods are placed inside the rotating drum which when combine with ore will break up the larger particles until the desired particle size is achieved. Mill liners and grinding media (balls or rod) sizes along with ore residence time and circulating load all have impact on mill efficiency. Power consumption is largely impacted by the grind-ability index as determined by testing and other characteristics.

Water is often added to base metal ores to improve efficiency.

Wet and dry grinding with continuous or batch feed are used. Air swept and nitrogen purged options are also available.